eddy current hardness tester|how eddy current testing works : OEM Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique used to detect and characterize surface and near-surface defects in conductive materials. It relies on the principle of electromagnetic induction. Cinemas; Araranguá-SC; Águas Claras-DF; Blumenau-SC; Cachoeirinha-RS; Gravataí-RS; Itajaí-SC; Jaraguá do Sul-SC; Lajeado-RS; Limeira-SP; Palhoça-SC; Passo Fundo-RS; .

{plog:ftitle_list}

web@Yiny_Leon_YinyLeon. 13.7K subscribers. 211 photos. 67 videos. 34 links. . VIEW IN TELEGRAM. 0:10. This media is not supported in your browser. VIEW IN TELEGRAM. .

Eddy current testing is one of several non-destructive testing methods that uses the electromagnetism principle for flaw detection in conductive materials. A specially designed coil energised with an alternating-current is placed in . The same eddy current testing devices can be used for material mix-up testing as well as for hardness testing. Magnetic environmental influences in the production process Crucial aspects to consider in eddy .

Eddy current testing is a non-destructive method for testing metal surfaces for defects such as longitudinal and transverse cracks. The type of testing performed, using comprehensive through-type coils or rotating probes, .

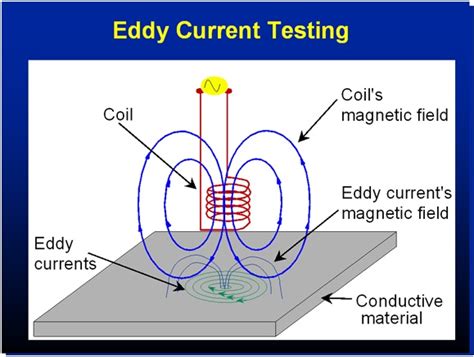

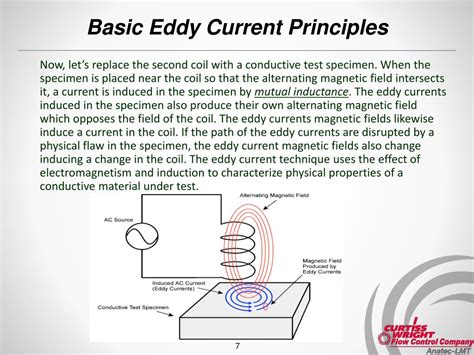

Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique used to detect and characterize surface and near-surface defects in conductive materials. It relies on the principle of electromagnetic induction.The principle involves the generation of alternating current within a coil or conductor, engendering a dynamic magnetic field in its vicinity. When this energized coil approaches a conductive material, such as a metal component, it imparts within the material circulating electric currents – referred to as "eddy currents."

The eddy current method can be used for very different applications. In this video we would like to show how the FOERSTER DEFECTOMETER is used to sort differ. Aluminum alloys are heat treated to provide optimal material properties for use in a variety of applications. However, when exposed to abnormally high temperatures, an evaluation must be performed to determine if the aluminum component has been compromised. Nondestructive evaluation of aluminum alloys, by means of electrical conductivity and .

who does eddy current testing

Digital eddy current test instrument for nondestructive testing of mass-produced parts, metal components, and semi-finished products for material properties such as hardness, case depth, structure, tensile strength, heat treatment, or alloy using .

Eddy current testing instruments can perform a wide variety of tests, depending on the type of probe being used. . In addition to finding cracks, eddy current testing can also be used to check metal hardness and conductivity in applications where those properties are of interest, and to measure thin layers of nonconductive coatings, such as .Get all the features you need in an eddy current tester, including multiple frequencies, accurate readings and logging, all from leading brands like AutoSIGMA. Contact: (913) 685-0675. Products. All Products . –+ Hardness Testers - Portable –+ – .

4.1.6.2 Effect of Permeability on Eddy Currents.Eddy current testing of ferromagnetic parts is usually limited to . 4.1.6.7 Heat Treat Condition or Hardness.Heat treating (or age hardening) a metal changes its hardness and its electrical conductivity. Just as above, the aluminum alloys have been the most investigated for the hardness .

An eddy current tester sends an alternating current through a coil which generates an oscillating magnetic field. When the probe is placed near the surface of a conductive metal, a circular flow of electrons, an eddy current, begins to move through the metal and generate its own magnetic field which interacts with the magnetic field created by .

how eddy current testing works

Learn how eddy current non-destructive test systems integrate into production lines, provide quality assurance, & reduce scrap, warranty, and liability costs. . Ball Bearing Hardness Test Piston Ring Orientation Check High-Speed Thread .

Eddy current testing uses electromagnetic induction to detect defects in both ferrous and non-ferrous materials by inducing an eddy current field in the specimen under test. A variety of inspections can be performed with eddy current testing and it is typically used for surface and near-surface flaw detection, metal and coating thickness .With the right eddy current testing devices, technicians can carry out successful hardness testing and validate that the hardness meets specific regulations. With the devices we recommend, technicians can rapidly find flaws and remove the faulty parts from the assembly line, enhancing safety and productive operations.

Metaltest provides electrical conductivity testing for determining the electrical conductivity of nonmagnetic metals using the electromagnetic (eddy-current) method. This test is applicable to metals that have either a flat or slightly curved surface and includes metals with or without a thin nonconductive coating.In its most basic form — the single-element eddy current testing probe — a copper wire is excited with an alternating electrical current. This wire produces a magnetic field around itself in the direction ascertained by the right-hand rule. .

Eddy current hardness testing. Testing materials or products for hardness is a common practice in many industries for ensuring that the items being tested can withstand normal wear and tear. Eddy current hardness testing is one of the best NDT methods used for this purpose.What is eddy current testing and how do inspectors use it? This in-depth guide covers methods, common applications, and more. Sales. NON DESTRUCTIVE TESTING. Acoustic Imaging. . Hardness Testers. alphaDUR mini UCI Hardness Tester; alphaDUR mini II; GE MIC 10; GE MIC 20; Proceq Equotip 3; Proceq Equotip 2; Proceq Equotip 550;

Hardness Sorting is a specialized application of Eddy Current Testing that deals with distinguishing materials based on hardness levels. This technique plays a vital role in industries such as automotive, aerospace, and manufacturing, where material hardness directly impacts the performance and lifespan of components.DOI: 10.1016/J.NDTEINT.2006.04.005 Corpus ID: 138318799; Eddy currents and hardness testing for evaluation of steel decarburizing @article{Mercier2006EddyCA, title={Eddy currents and hardness testing for evaluation of steel decarburizing}, author={David Mercier and Jacky Lesage and Xavier Decoopman and Didier Chicot}, journal={Ndt \& E International}, .We are the manufacturer & supplier of Eddy Current Tester, Materialography, Metallography including eddy current tester & Dimensional Equipment. 1038521826884939 . we can create customized machines such as hardness tester, microscopes and automatics cutting machines in our in-house lab. We have dedicated engineers and professional having rich .VARIMAC® VI EDDY CURRENT COMPARATOR Tests Hardness, Alloy, Dimensions and Physical Characteristics in Metal Test and sort fasteners, bearings and other cold formed pieces using 100% nondestructive testing.Check for hardness and correct grade in wire and bar.Test ferrous (magnetic) or nonferrous (non-magnetic) material.Use with MAC® Parts Gate for high .

eddy current testing pdf

In order to develop a correlation between the eddy current and Rockwell hardness (HrB) test methods, two tests were conducted. 380 samples (38 sets of 10 samples) were tested with a Rockwell hardness tester and the eddy current test system. Improperly hardened specimens were included in the test batch.Eddy current testing is a non-destructive method for testing metal surfaces for defects such as longitudinal and transverse cracks. The type of testing performed, using comprehensive through-type coils or rotating probes, depends on the type of defect. . Typical test tasks include hardness checks, material differentiation and sorting. Find .

The SonoDur 3 is the latest generation of portable UCI Hardness Tester from NewSonic. Featuring the Android Operating System, the SonoDur 3 has data transfer and export functions via USB, WLAN or Bluetooth with virtually unlimited storage capacity of measurement data. Replaces MIC10/MIC20 & Conforms to ASTM/DIN The SonoDur 3 (and SonoDur 2) replaces . Eddy current is a non-destructive testing technique that uses a probe to induce small alternating current within the part that is being examined. Eddy current testing produces a rapid and easily used method of determining the conductivity of a part. A typical eddy current conductivity tester is shown in Figure 3. Reference standards are .

abs thickness measurement rules

accurate thickness measurement of graphene

Idle Farming Business is an idle game where you take control of a cute plot of land to build up your own farm! There are tons of different vegetables for you to grow and expand your business! From simple potatoes and carrots to more interesting radishes and beets.

eddy current hardness tester|how eddy current testing works